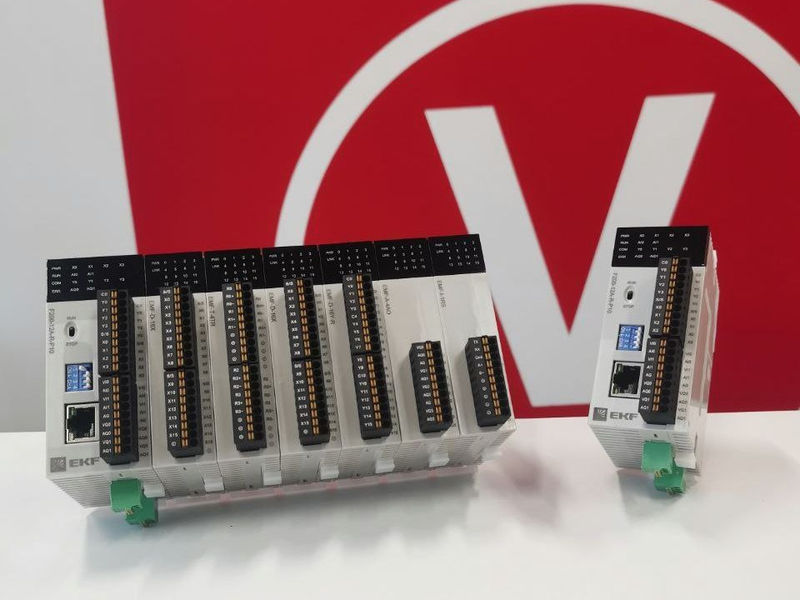

PRO-Logic programmable controllers

February 28, 2022

EKF has a long-awaited new product in our automation equipment range. It is a programmable logic controller (PLC). It’s time to present this product in detail.

PRO-Logic function

PLC PRO-Logic is designed to build systems for monitoring and automating control of various technological systems: lighting, ventilation, heating, water supply, water treatment, conveyors, packing belts, etc.

PRO-Logic main data

- 24 V DC power supply

- input/output signals: discrete and analog

- types of output signals: 2 A e/m relays or NPN transistors

- interfaces: RS-485 and Ethernet

PRO-Logic controller features:

1. Reliable and convenient mounting

- Removable spring-type terminals

- Simple connection

- Time saving

- Reliable connection

- Vibration resistance

- No broaching required

2. Integration into monitoring and control systems

- Integrated standard interfaces for connection to peripheral devices (sensors, frequency converters, operator’s panels) and control systems (OPC, SCADA )

- Ethernet (protocol Modbus TCP)

- RS-485 (protocols Modbus RTU, Modbus ASCII)

3. Scalability

- Increase in the number of input/output points to 256!

- Extension modules:

- Discrete modules

- Analogue modules

- Temperature modules (thermocouples, thermal resistance)

- Interface modules (RS-232/485)

4. Indication of system status

- Visual control:

- Input and output status

- Device status

- Available errors

- Communication with peripheral devices

5. Saving space

Compact size and DIN rail mounting

6. High-speed computation and control

High speed inputs and outputs 200 kHz

7. Connection of temperature sensors

- Thermal resistances: Pt100, Pt1000, Cu50, Cu100

- Thermocouples: S, K, E, J, B, N, R, Wre3/25, Wre5/26

8. Easy configuration and programming

- PRO-Logic master: free project development environment.

- Standard programming languages: FBD, LD, IL.

- Integrated library with support for 188 functions.

- Built-in simulator for system debugging.

PRO-Logic application areas

- Heating, ventilation, air conditioning.

- Metal processing.

- Woodworking.

- Water treatment, water supply.

- Food processing industry.

- Conveyors, packaging, bottling.

Benefits of using PRO-Logic controllers:

- Process optimization and operating cost reduction

- Equipment condition monitoring and predictive review

- Stability and safety of system operation